When you’re budgeting for excavation support, understanding soldier pile and lagging wall cost helps you plan accurately.

Deep excavation often relies on reliable excavation support systems.

Among them, a soldier pile and lagging solution offers fast construction and versatility.

In this guide, we break down the main factors that shape your total investment.

We cover material and labor costs, design choices, regulatory fees and safety requirements.

We understand that unexpected expenses can derail your schedule.

That’s why we break down each cost factor clearly.

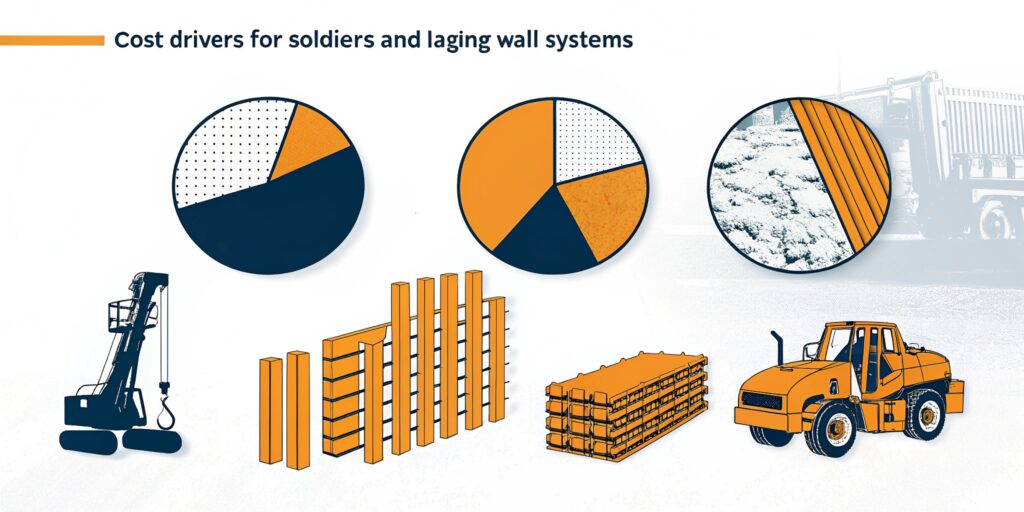

Understand cost drivers

Several variables influence what you pay.

Breaking them down helps you avoid surprises.

Material choices

Your selection of soldier piles and lagging panels sets the baseline price.

Common pile options include H-piles driven or drilled into the ground.

For lagging, timber usually costs less per board than precast concrete.

Shotcrete offers a balance between speed and strength.

Labor and equipment

Crew expertise and gear rentals make up a large share of your budget.

You need operators for pile installation and workers for lagging placement.

Equipment such as excavators and vibratory drivers adds to cost.

Working with experienced crews can cut hours and reduce your total spend.

Site conditions

Your soil type, water table and access affect project scope.

Cohesive clays may require extra reinforcement.

High water tables often need dewatering, which adds labor and equipment fees.

Evaluate design requirements

Your approach to soldier pile and lagging wall design sets your specs.

We know design choices can feel complex.

Here’s how to align specs with your budget.

Pile spacing and embedment

Closer pile spacing increases material use and labor.

Deeper embedment boosts stability but adds drilling time.

You may need tiebacks or walers if you exceed cantilever capacity.

Lagging panel selection

Panel thickness and material choice shape performance and price.

Timber panels suit short-term jobs, while precast concrete lends long-term durability.

For more on materials, see our lagging panel material options.

Factor in regulations and safety

Compliance and safety play critical roles in cost.

I know keeping up with permits and safety rules takes time.

Let’s simplify the process.

Permit and compliance

You must secure local permits and meet building codes.

Fees vary by jurisdiction and can range from a few hundred to several thousand dollars.

Checking local rules early prevents delays.

Excavation safety measures

Implementing excavation safety measures protects your team and avoids stoppages.

You should budget for training, inspections and safety gear.

Regular checks reduce the risk of fines.

Compare temporary and permanent solutions

Temporary shoring often lowers initial cost but adds removal fees.

Permanent options cost more upfront yet reduce long-term maintenance.

| Factor | Temporary system | Permanent system |

|---|---|---|

| Lifespan | 1-2 years | 20+ years |

| Initial cost | Lower | Higher |

| Removal | Required | Not required |

| Material | Timber, steel plating | Precast concrete, shotcrete |

Estimate total investment

Follow a clear process to get a reliable estimate.

- Perform a geotechnical survey and assess site data

- Define design specs including pile spacing, embedment depth and panel type

- Request bids from qualified contractors

- Add a 10-20% contingency for unforeseen conditions

- Factor in ongoing maintenance and dewatering costs

To refine your budget further, explore our excavation shoring cost analysis for regional fee breakdowns.

We understand that balancing cost and performance matters to you.

Why choose RuffHouse Construction LLC

- Local expertise covering WA and OR projects

- Fast installation to keep your schedule on track

- Strict compliance with all safety and building codes

When you’re ready to secure reliable shoring for your excavation, get in touch today.

Project questions answered

What factors most affect soldier pile and lagging wall cost?

Material, labor, design specs and site conditions drive most of the budget.

Can I use soldier pile walls in high water table conditions?

Yes, but extensive dewatering and a water-tight lagging system are required.

How long does installation typically take?

You progress in lifts of about 5 feet, averaging 1-2 days per lift.

What maintenance is required after installation?

Regular inspections for lagging integrity and monitoring of surface settlement.

How do permit fees vary by location?

They differ widely. For details see our excavation shoring regulations.

Ready to start your own soldier pile wall project in Seattle, Tacoma, or anywhere in Puget Sound?

Learn how Ruffhouse Construction delivers safe, code-compliant soldier pile and lagging wall installations for any site.

See our Soldier Pile Installation Services for details and request a free estimate today.